I have bought a turbo usually fitted to an L series engine to fit as an upgrade to the prima engine.

As the engine has the same bore and stroke the turbo is a good match. Dan (ETV) pointed me in the right direction and steered my decision of the chosen turbo.

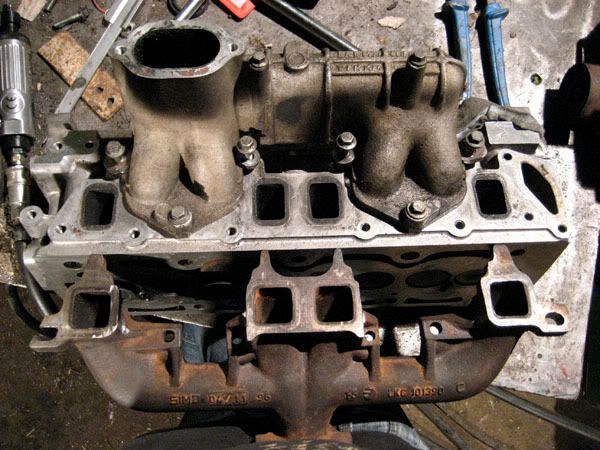

The internals of the manifold are that much smaller I'm going to open up the ports to match the head. Under inspection the final dimension within the 2 turbos are similar in size. The L series has smaller exhaust ports than the prima and there for a faster flowing exhaust.

As long as where the exhaust ports meet the manifold there is no huge lip to interrupt the gas flow then all should be well. It looks doable to me!!

I will get some better pics up soon to show what I am up to!!

I have posted up on the MG Rover forum as I need some parts, there is a fairly active community with available parts for this engine!

The turbo arrived with out the exhaust elbow which I have located there, I also managed to foul the manifold face (grinding edges off to fit onto head) and located another!

I will update with pics to show progress!

As the engine has the same bore and stroke the turbo is a good match. Dan (ETV) pointed me in the right direction and steered my decision of the chosen turbo.

The internals of the manifold are that much smaller I'm going to open up the ports to match the head. Under inspection the final dimension within the 2 turbos are similar in size. The L series has smaller exhaust ports than the prima and there for a faster flowing exhaust.

As long as where the exhaust ports meet the manifold there is no huge lip to interrupt the gas flow then all should be well. It looks doable to me!!

I will get some better pics up soon to show what I am up to!!

I have posted up on the MG Rover forum as I need some parts, there is a fairly active community with available parts for this engine!

The turbo arrived with out the exhaust elbow which I have located there, I also managed to foul the manifold face (grinding edges off to fit onto head) and located another!

I will update with pics to show progress!

Comment